In the development of bathroom spaces, the evolution of bathtub materials has always been a benchmark for technological iteration and consumer upgrading.The rise of acrylic bathtubs is a history of evolution from an alternative material to an industry standard.It has completely reshaped the modern understanding of the bathing experience.

Preliminary substitution (1970s – 1990s)

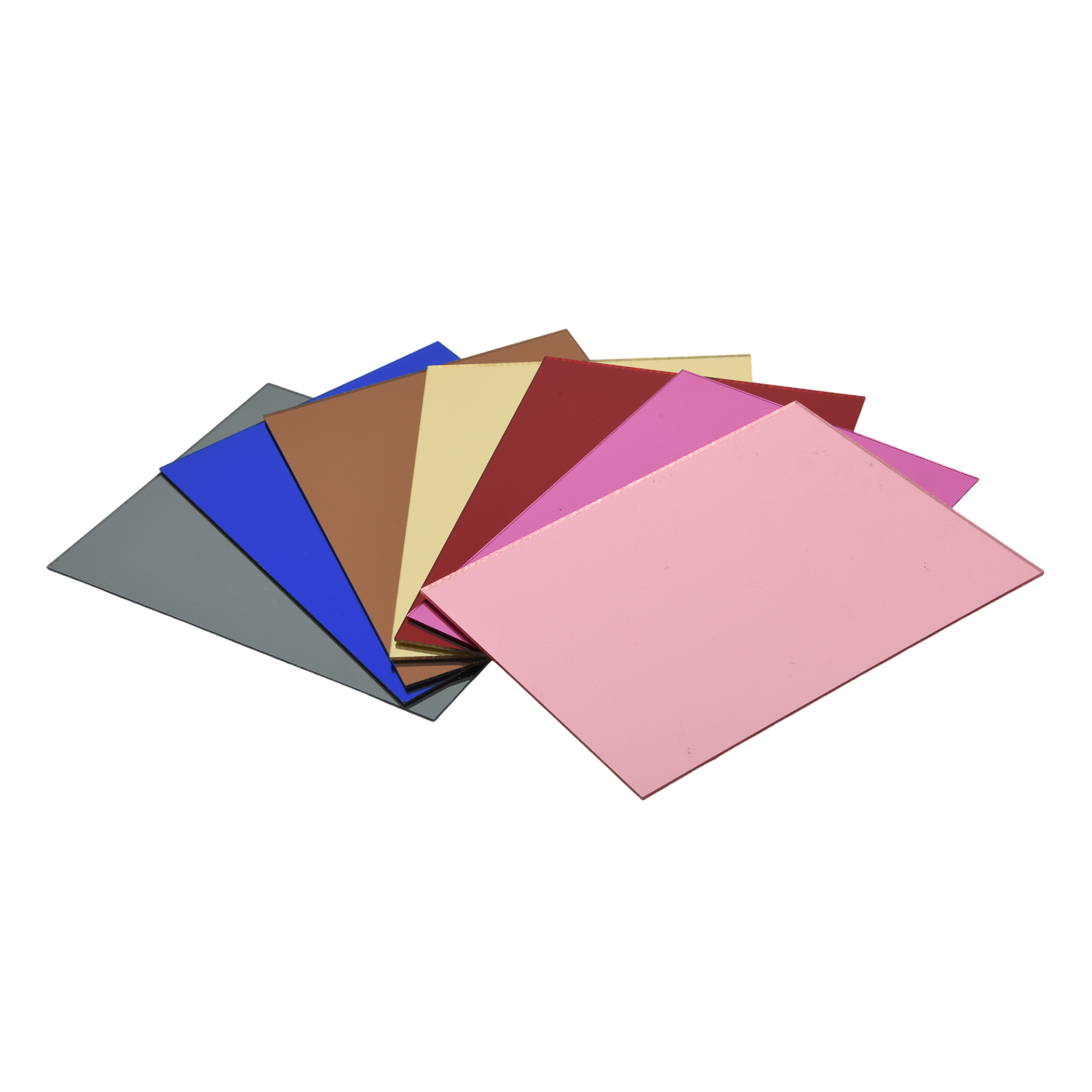

The prototype of acrylic bathtubs emerged in the 1970s and initially entered the market as an economical alternative to the traditional cast iron enamel bathtubs.Early products were mainly single-layer extruded sheets, manufactured using simple thermoforming techniques. Although they achieved lightweight construction, they had obvious limitations in terms of insulation, surface hardness, and design flexibility. During this period, acrylic bathtubs were more of a “practical” budget option and had not yet demonstrated the potential for a revolutionary change.

Technological Breakthroughs (2000s-2010s)

Entering the new century, key breakthroughs were made in multi-layer composite technology and surface treatment processes.By applying the “ABS/acrylic composite laminated structure”, the bathtub not only maintains excellent surface gloss but also achieves higher structural strength and impact resistance.The widespread use of nano-scale UV-cured coatings has increased surface hardness from 2H to over 4H, with wear and scratch resistance comparable to ceramics.During this period, acrylic bathtubs began to shed their “cheap” label and gradually entered the mid-to-high-end market.

Intelligent Integration (2020s to present)

At the current stage, acrylic bathtubs have evolved into the core carriers of smart bathroom systems.The new generation of products have achieved seamless integration and embedded functional integration through an integrated molding process: the LED atmosphere lighting system, intelligent constant temperature control, hydraulic massage module, and even the sound wave resonance device can all be perfectly integrated into the smooth curved surface design.The plasticity advantages of the material are fully utilized, from traditional rectangular shapes to round, fan-shaped, diamond-cut styles, and even to asymmetrical designs completely customized according to ergonomics. Acrylic bathtubs truly achieve a ‘design-driven function’.