Recently, a purchaser representative from Oman visited Zhejiang Arris Import and Export Co., Ltd.The purpose is to conduct an on-site inspection of the company’s acrylic product production line for learning and procurement.Ms. Linda, the company’s sales general manager, accompanied and received the guests throughout the process and gave a detailed introduction to the production workshop and the production process.

The purchaser thoroughly toured the core production areas of Arris Company, visiting the entire manufacturing process of acrylic sheet, which includes all stages from raw material storage, raw material pre-treatment, board formation and heating, demolding, coating, and packaging, as well as quality inspection.He showed a strong interest in the highly automated equipment and the rigorous quality control system in the workshop.

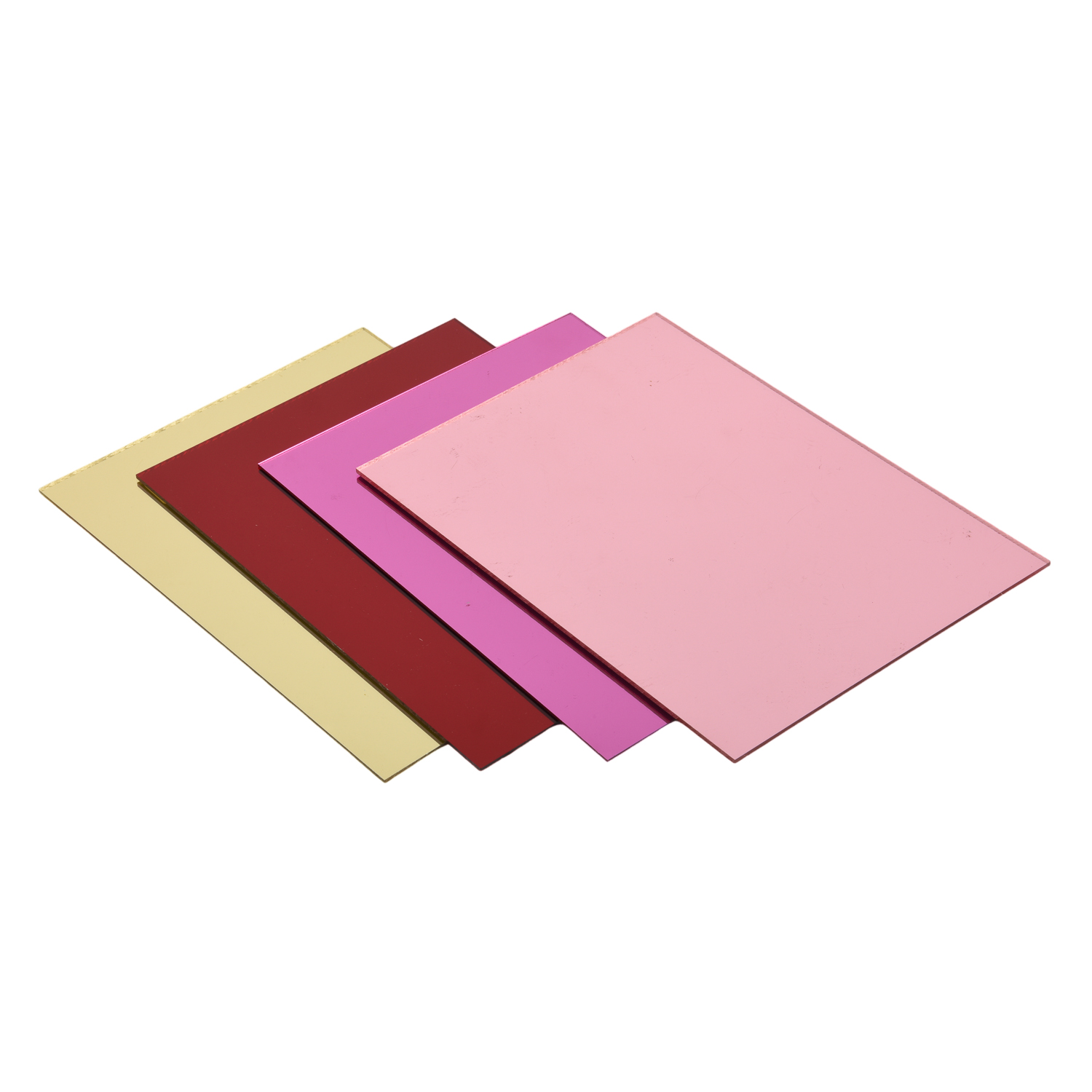

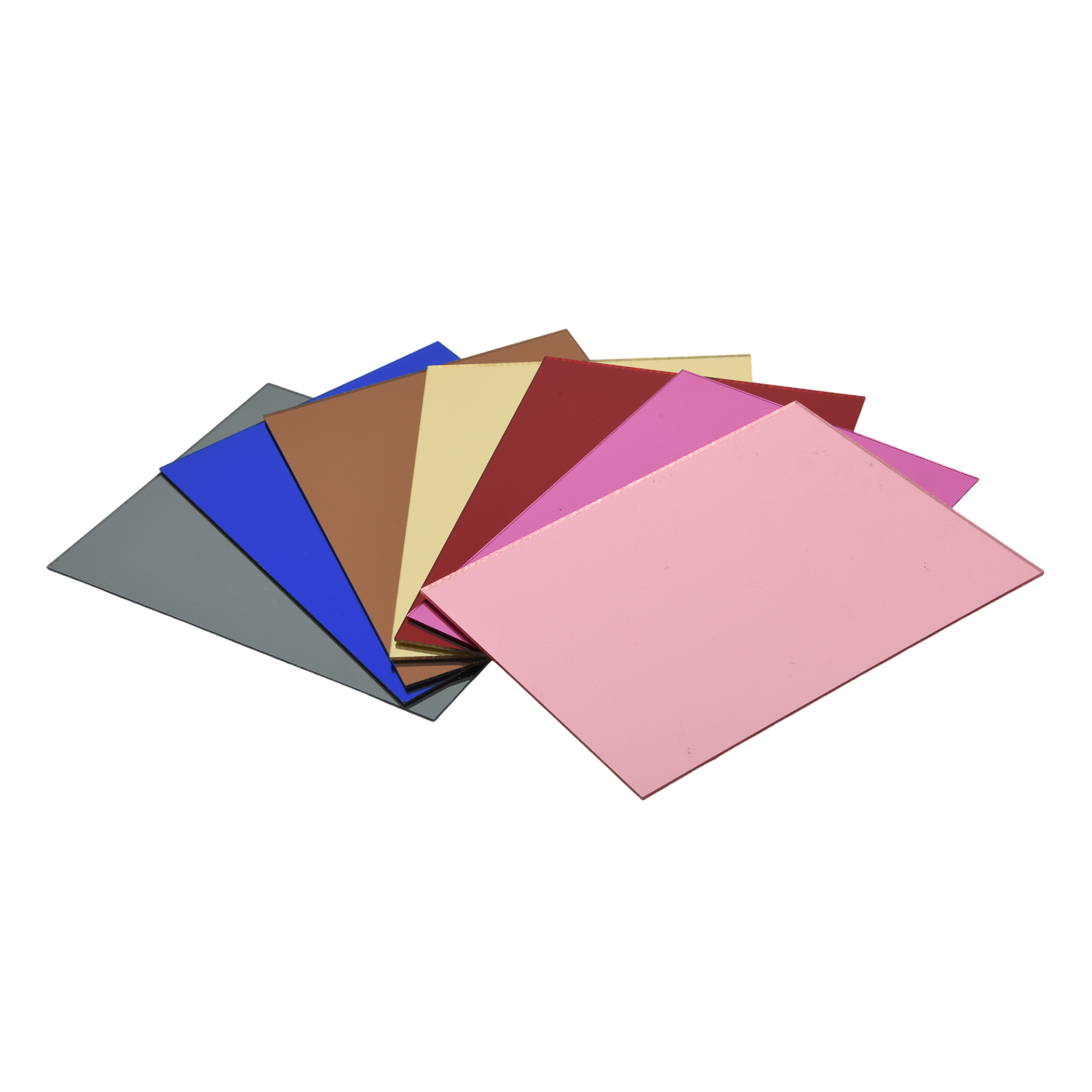

Linda first introduced the company overview and the market applications of acrylic products to the purchaser.Subsequently, on the production line, she, based on specific processes, elaborately explained the technical advantages and strict standards of Arris Company from the raw material to the production of acrylic sheets.She emphasized, We always regard quality as our lifeline.Starting from the selection of top-quality new MMA particles from Mitsubishi in Japan, to the implementation of a full-process standardized management system,then the self inspection and mutual inspection after each process.We ensure that all acrylic sheets manufactured by us have high transparency or coloration,excellent weather resistance, outstanding impact strength, and long service life.

When visiting the laboratory, Linda gave the client a detailed introduction to our unique domestic DCS system. This is a pouring acrylic production line that can achieve fully automated and precise production. The single-line production capacity has increased by 1.5 times compared to before, and the product quality is even better.In the quality inspection process, the purchaser witnessed multiple strict quality inspection procedures including thickness measurement, transparency testing, scratch resistance and impact testing.He highly praised the stability and reliability of the products of the Arris Company.

Through this on-site inspection, foreign buyer was deeply impressed by Arris’ strong production capacity, innovative technology, and international quality management.The detailed production process witnessed with his own eyes and Linda’s professional explanation strengthened his confidence in establishing a long-term and stable partnership with Arris Company.Make him look forward to jointly exploring the market in the future.

Before parting, Linda and the foreign purchaser took a group photo in front of the huge raw material barrel.

We highly value the opportunity for direct communication and on-site inspections with international clients.

Not only can it demonstrate our capabilities, but it is also an important way for us to understand the market and improve the quality of our products.Arris looks forward to working with global partners to provide the highest quality acrylic solutions.

Information about Arris:

Zhejiang Arris In & Out Co., Ltd. is an enterprise specializing in the research, production and sales of acrylic (PMMA) sheets and their derivative products.The company has a modern production base, the most advanced production line in Asia, and an annual output of 30,000 tons.The product is widely used in various fields such as advertising decoration, bathroom,projects,household items, display props, lighting and so on.It sells well in domestic and foreign markets with its excellent quality and competitive price.