The aircraft window, serving as a medium connecting passengers to the sky, requires not only exceptional safety but also clarity and transparency.In traditional perception, glass is often regarded as the preferred material.However, after aviation acrylic boards rose to prominence in the realm of pliable materials, they are now rewriting the rules of this field.

Aviation Acrylic sheets are not a newcomer to the aviation field.As early as during World War II, the superior properties of aviation-grade acrylic had already drawn the attention of military forces.For instance, impact-resistant aviation acrylic sheets are used in fighter jet windshields and tank observation windows due to their high light transmittance and impact resistance.Even it became a key material for bulletproof testing of the American M16 rifle.This historical accumulation laid the foundation for the application of cell cast acrylic sheets in modern aviation.

It is worth mentioning that some of the window frames and interior transparent components of modern civil aviation aircraft are also made of acrylic material.Its lightweight feature (with a weight only half that of glass) significantly reduces the aircraft’s overall weight, thereby enhancing fuel efficiency.

Performance Advantage:

Safety and Durability

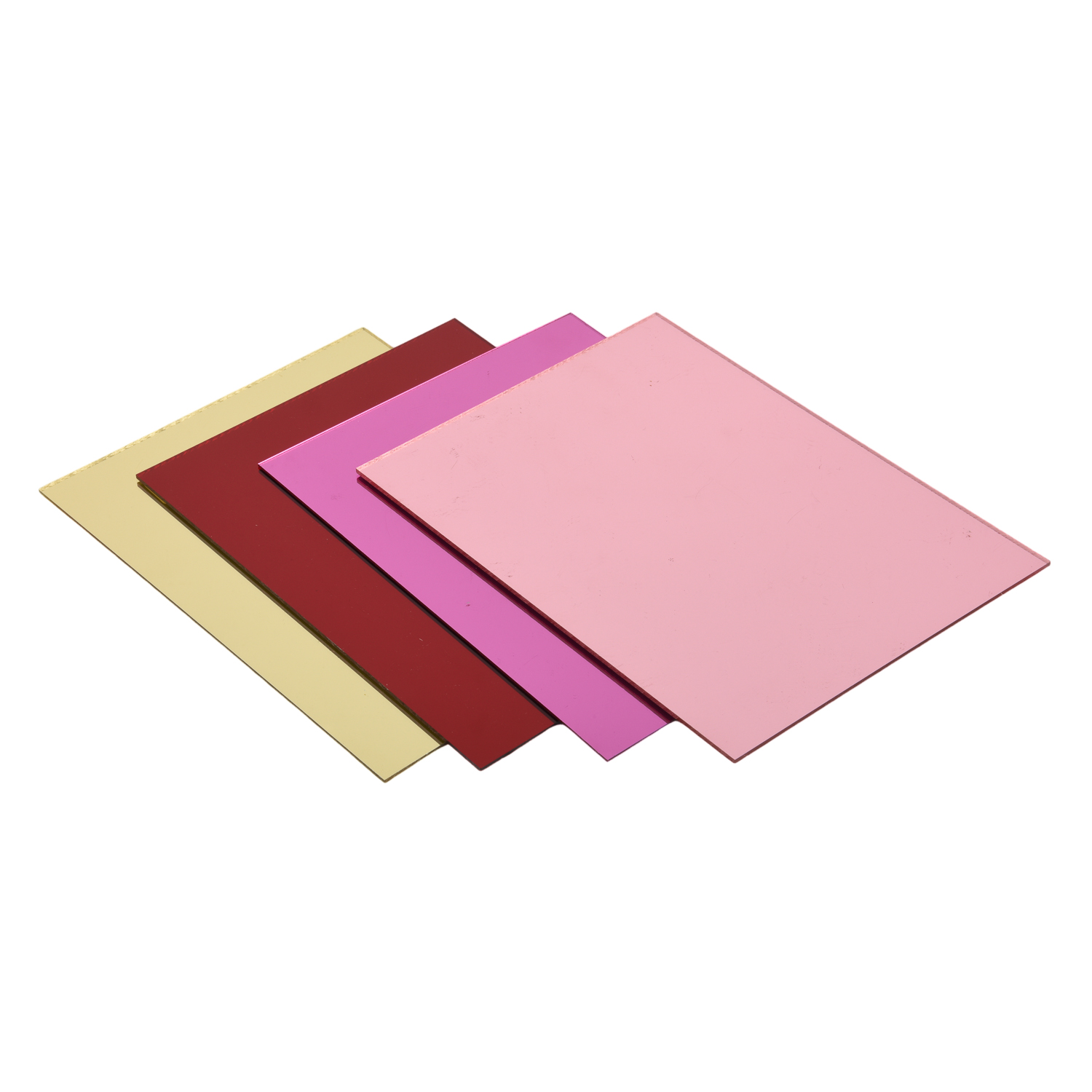

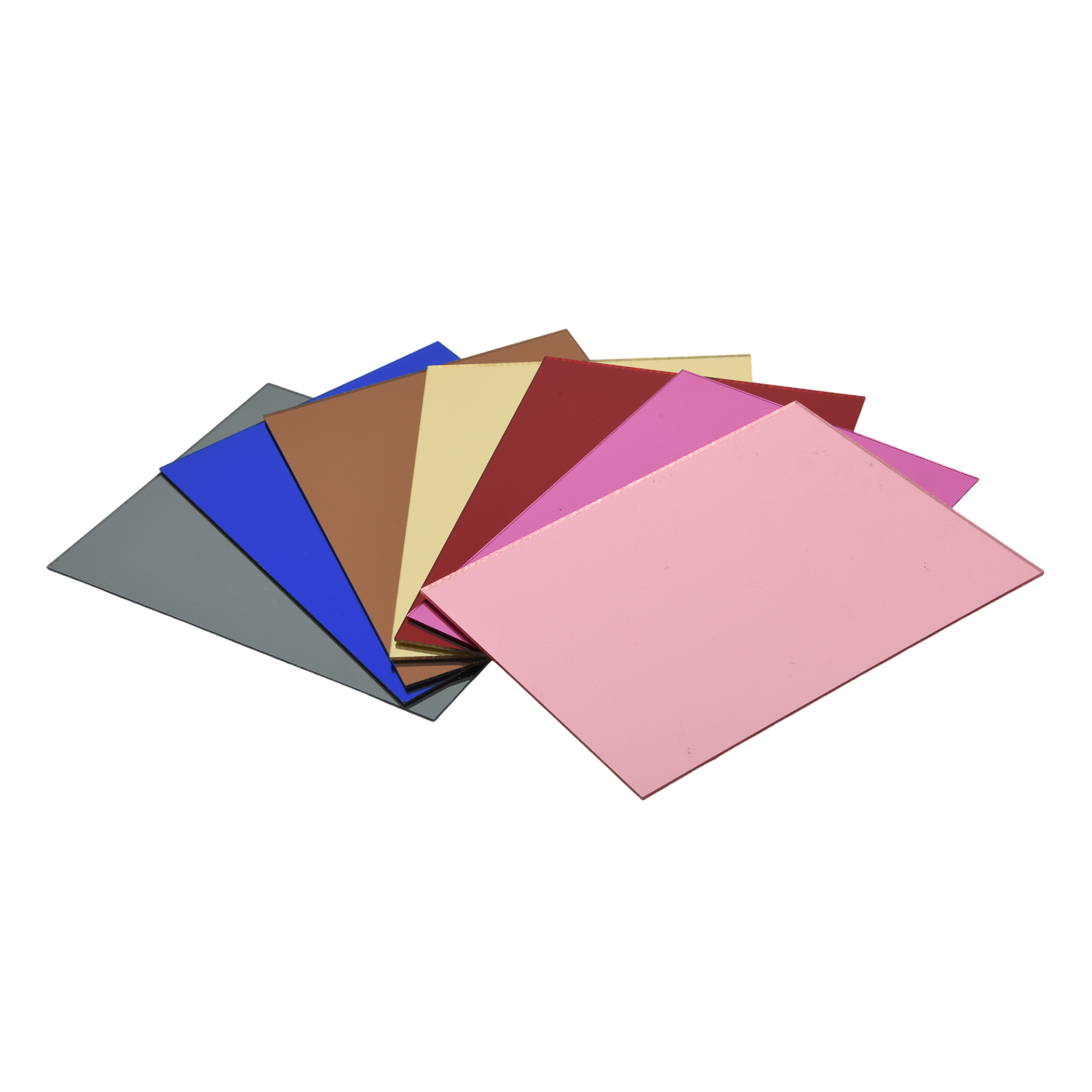

The impact strength of 81-color US Military acrylic sheet is 17-20 times that of ordinary glass.Even in the case of extreme temperature differences at high altitudes or unexpected impacts, it can effectively prevent the risk of fragmentation.Ensure passenger safety.Arris’ impact-resistant aviation acrylic sheet has extremely strong weather resistance.It can resist UV radiation and low temperature environments for a long time, avoiding yellowing or brittleness.

Optical Performance

Aircraft windows must ensure clear visibility for passengers.The light transmittance of acrylic sheets is generally as high as 92%, far exceeding the 85% of ordinary glass.This feature not only enhances the viewing experience, but also reduces the energy consumption of cabin lighting.

Lightweighting and Malleability

Impact-resistant aviation acrylic sheets are easy to cut, bend, and thermoform, meeting the complex design requirements of aircraft streamlined portholes.Meanwhile, its lightweight feature (with a density of only 1.18g/cm³) offers more possibilities for reducing the weight of the body.

The hot topic in recent years: low altitude aircraft, Military Specification MIL P-8184F acrylic panels can also occupy a place.During low-altitude flights, it is inevitable to encounter incidents such as bird strikes and branches scraping.Acrylic board can withstand impact without breaking, improving the safety of aircraft.